Plating Services

We use automation to your benefit.

PLating Services

Automation

Learn MoreZinc

Learn MoreAnodizing

Chemical Film

Passivate

Automation

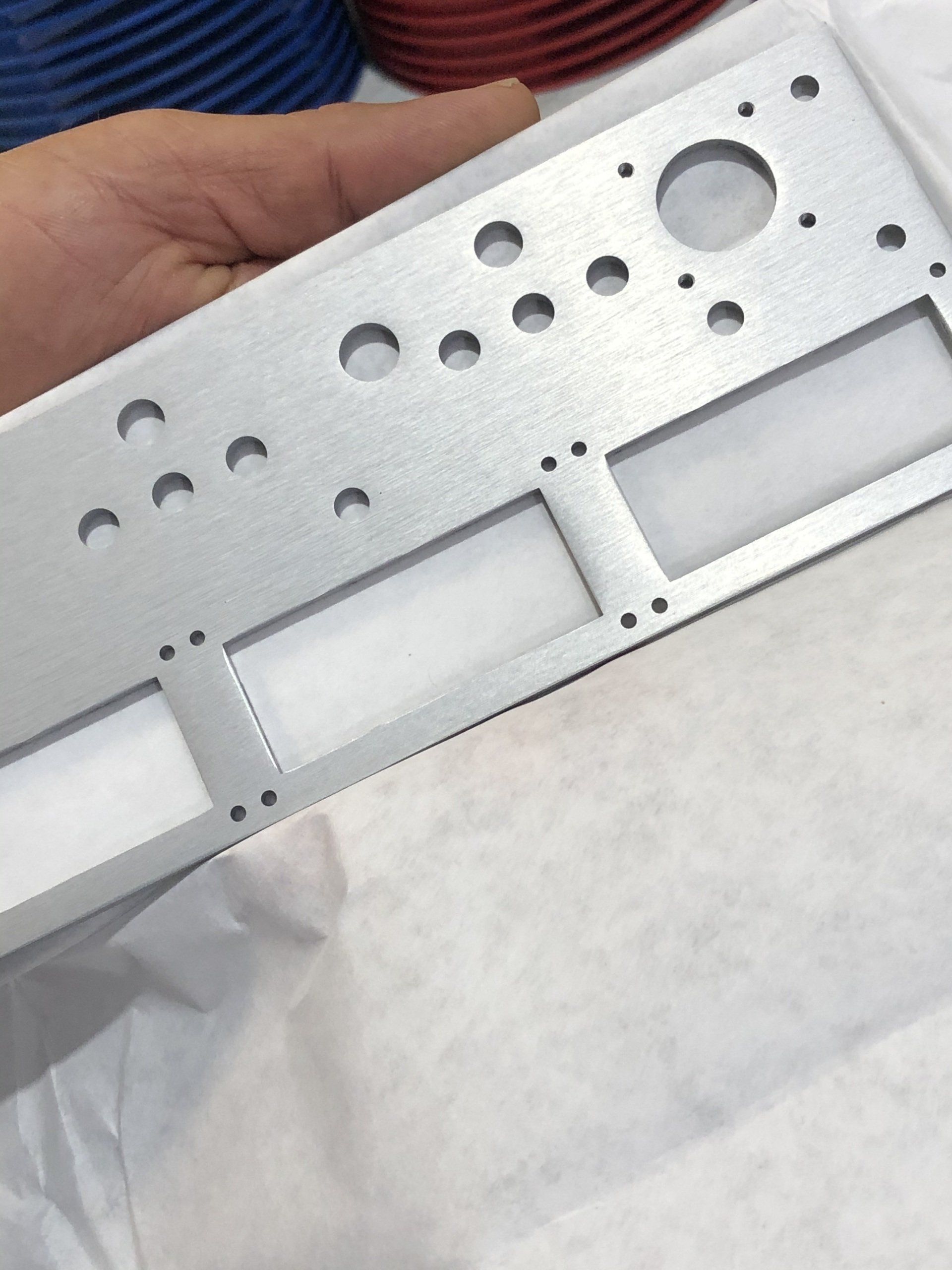

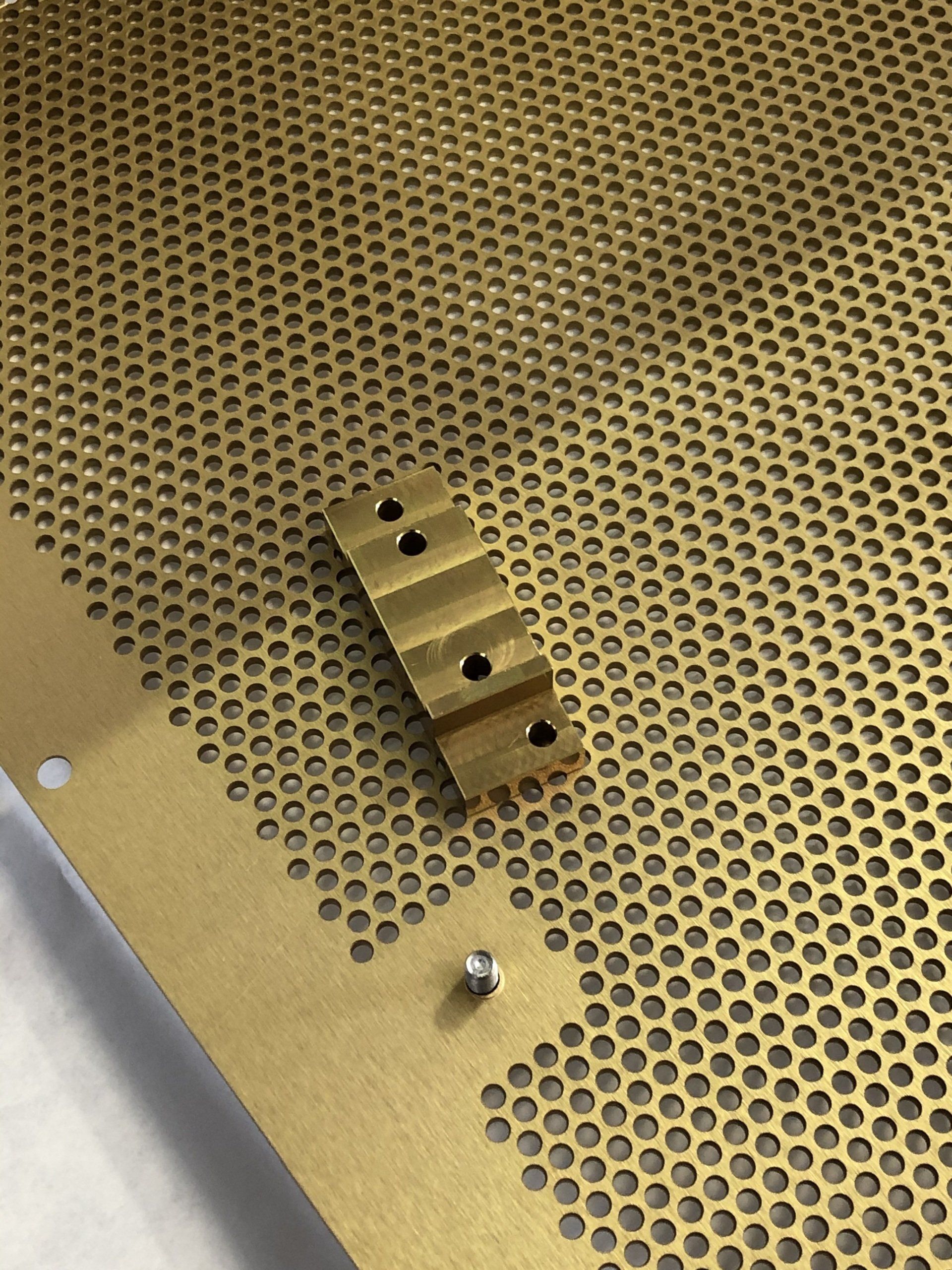

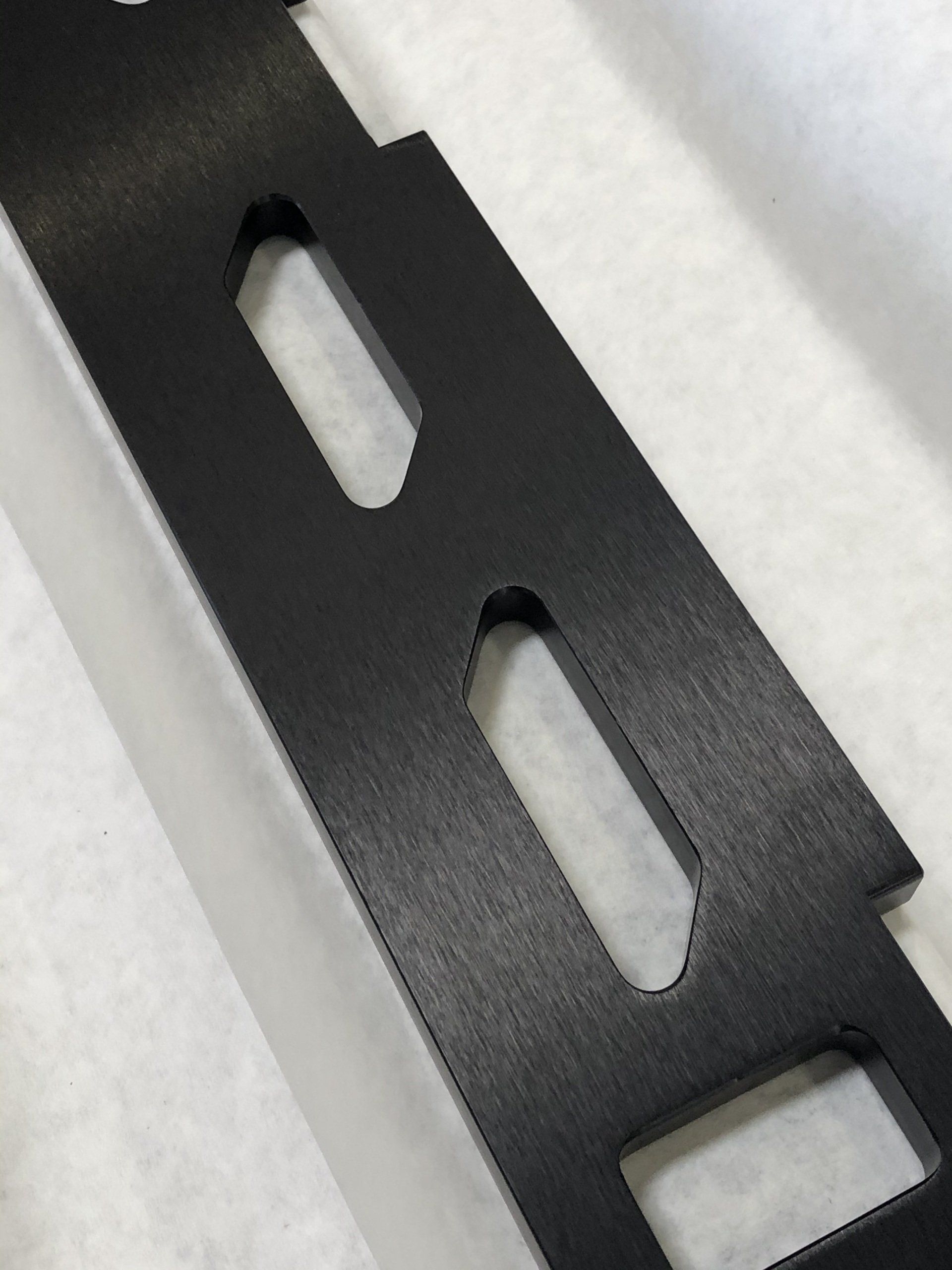

At GMP Plating, Inc., our USA and Guadalajara, Mexico facilities are equipped with advanced technology to deliver superior plating that meets the strictest industry tolerances for clients in Medical, Communication Server Systems, and beyond. With over 25 years of experience since our founding in 1999, we have developed a patented computerized plating monitoring system to ensure consistent, variance-free results every time. Our in-house laboratory, outfitted with state-of-the-art equipment, rigorously tests multiple elements to verify that our monitoring system performs to exact specifications. Additionally, we conduct regular salt spray tests, subjecting samples to rigorous chamber testing to guarantee the highest quality and durability for our customers’ plating needs.

GMP Plating, Inc. specializes in electrodeposited zinc coatings on iron and steel articles for superior corrosion protection, excluding zinc-coated steel wires or sheets. Available in four standard thickness classes in the as-plated condition or with one of three supplementary finishes, our zinc plating services ensure durability for industries like Medical and Communication Server Systems. We meticulously prepare surfaces through pre-plating basis metal cleaning, pre- and post-coating treatments to minimize hydrogen embrittlement risks, reactivation, and supplementary processes. All coatings are sampled, tested, and verified to meet rigorous standards for appearance (including luster and workmanship), thickness, adhesion, corrosion resistance, and hydrogen embrittlement prevention, delivering consistent quality from our USA and Guadalajara, Mexico facilities.

Zinc

GMP Plating, Inc. offers advanced anodizing solutions from our USA and Guadalajara, Mexico facilities, serving industries like Medical and Communication Server Systems with precision and quality.

Type II Anodizing:

- Sulfuric Acid Anodize (SAA): Designed for parts requiring hardness and abrasion resistance, SAA creates a harder surface than chromic anodizing, enhancing durability.

Type III Anodizing:

- Hardcoat Anodize: Utilizes a sulfuric acid bath to form a significantly thicker anodic coating than standard SAA, providing superior hardness and wear resistance for demanding applications.

Anodizing

Chemical Film

GMP Plating, Inc. provides chemical film coating, also known as Alodine, a chemical conversion process designed to enhance corrosion resistance for aluminum components. Widely used in industries such as Medical and Communication Server Systems, this treatment passivates aluminum, creating a protective layer that prevents corrosion while serving as an excellent primer for paint or other coatings. The process preserves the aluminum’s original dimensions and surface properties, ensuring compatibility with subsequent finishes without altering the substrate. Applied at our advanced USA and Guadalajara, Mexico facilities, our chemical film coatings meet stringent industry standards, delivering consistent, high-quality results for both local and international clients.

Passivate

GMP Plating, Inc. offers expert passivation services for stainless steel components, utilizing a specialized process to enhance durability and corrosion resistance. Conducted at our state-of-the-art facilities in the USA and Guadalajara, Mexico, passivation removes free iron and contaminants from the surface of stainless steel, while simultaneously forming a thin, dense oxide layer that acts as a robust protective barrier. This treatment ensures long-lasting performance for applications in industries like Medical and Communication Server Systems, meeting rigorous quality standards and providing reliable protection for both local and international clients.